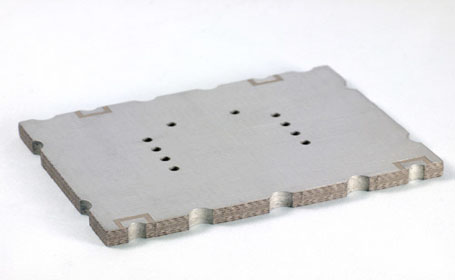

This multi-layer, high-frequency coupler, shown above, is used within a communications application for the telecom industry. Combining a variety of manufacturing services, Standard Printed Circuit Boards built 25 of these couplers for our client. We first sheared the material to size and fabricated the parts’ inner layers, which were then laminated. Our CNC drill formed all primary holes, as well as holes for plated castellations. A mixture of sodium and plasma etching was performed to prep the holes’ walls. Direct metallization was also carried out, using a polymer to produce conductive drilled hole walls.

After plating the couplers in copper, we etched the PCB, removing all surplus copper material. In addition, we endowed the parts with an immersion tin finish and applied all silkscreen graphics. The finished couplers measured 1.25″ x 1″, and possessed 6 separate layers. We also evaluated the product to ensure that all parts fulfilled client specifications.

The finished units were vacuum packed and shipped to our consumer in New York City. Meeting IPC-6018A Microwave End Product Board Inspection and Test standards, our couplers exceeded customer expectations for both design and quality.