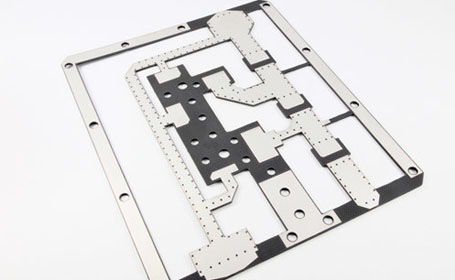

With a combination of specialized processes and equipment, Standard Printed Circuit Boards custom manufactured the double-sided glass-reinforced PTFE printed circuit board (PCB) displayed above. This PCB is used for controlled impedance within a microwave application.

Utilizing advanced photolithography and chemical etching, trace widths are controlled to a +/- .001″. CNC machines are used to bring the part to its final shape and size.

This board was manufactured and inspected to the specifications of IPC-6018 Microwave End Product Board Inspection and Test standards. Standard Printed Circuit Boards manufactured a total of 100 double-sided PTFE PCBs for this customer, fulfilling their expectations for both design and quality. All finished units were delivered to our customer’s facility in the Northeastern US.