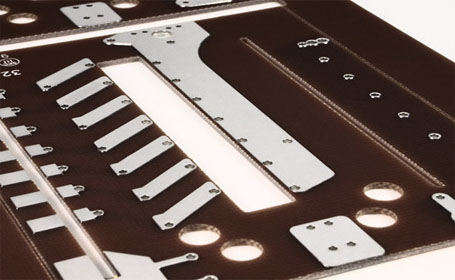

Double-Sided Polyimide High-Temperature PCB for Telecom / IT

Overview

When your telecom or IT systems demand reliability in extreme environments, our double-sided polyimide PCBs rise to the occasion. Engineered to endure continuous operation at 250 °C, these boards combine cutting-edge materials with precision manufacturing to deliver performance you can trust.

Why Choose Our Polyimide High-Temp PCBs?

-

Extreme Temperature Resilience

Survive where standard FR-4 fails. Our boards maintain stability and integrity in sustained 250 °C environments. -

Precision Manufacturing

We adhere to tight dimensional tolerances and rigorous processing to ensure consistency and performance. -

End-to-End Quality Control

From material selection to final inspection, every board is validated to meet industry standards and your specifications. -

Telecom & IT Focus

We’ve shipped over 1,000 such boards for telecom/IT applications—backed by a track record of performance and client satisfaction. -

Customizable Designs

While we list a nominal board dimension of 10.5″ × 3″, every project can be modified to fit your exact layout and mechanical needs.

Project Summary (Case in Point)

A major telecom client required 1,000 double-sided high-temperature boards. We produced them with the following:

-

Material: Polyimide laminate

-

Tolerances held to ±0.005″

-

Applied full spectrum of operations (metallization, etch, hot-air leveling, silkscreen)

-

Delivered to the southwestern U.S. on schedule

-

All units passed stringent standards (IPC-6012B, IPC-A-600, UL-94 V-1)

This project highlights our process control, reliability in harsh environments, and ability to scale while maintaining quality.

Ready to Get Started?

If you need PCBs that perform under extreme heat, let’s talk.

Request a Quote | Call us at 800-555-0980 | Email sales@standardpc.com

Key Features & Capabilities

| Feature | Details |

|---|---|

| Continuous Temp Rating | 250 °C |

| Layers | Double-sided |

| Material | Polyimide laminate (IPC 4101 / 41) |

| Tolerances | As tight as ±0.005″ |

| Typical Size | 10.5″ × 3″ (customizable per client specs) |

| Processing Steps | Shearing, CNC drilling & deburring, direct metallization, primary imaging, copper plating, etching, hot air solder leveling, silkscreen |

| Standards Compliance | IPC-6012B, IPC-A-600, UL-94 V-1 |

| Validation Methods | Visual inspection, in-process testing |