SPC Specializes in delivering quick turn prototypes, pre-production and medium volume production orders, on time, and with the highest level of commitment to our customers.

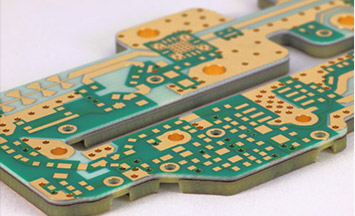

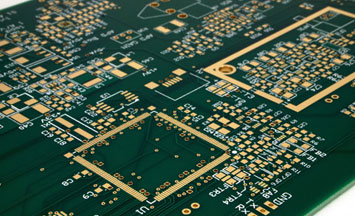

We are ISO 9001:2015, AS9100D & ITAR registered certified custom manufacturer of rigid printed circuit boards 1-24 layers utilizing standard FR4.

Request A QuoteCustom Printed Circuit Board Manufacturing

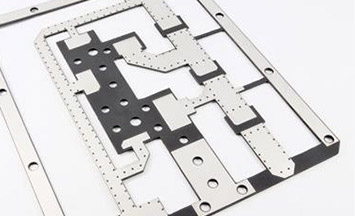

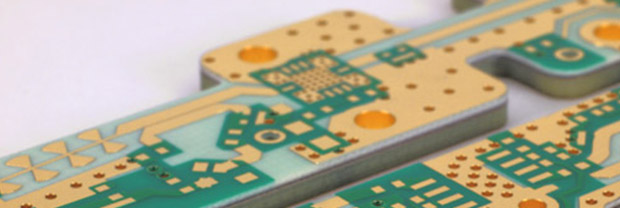

Standard Printed Circuits, Inc. is an independent manufacturer of rigid printed circuit boards up to 24 layers. Our expertise covers a broad range of advanced dielectrics including PTFE, ceramic loaded PTFE, TMM, Polyimide, Polyphenylene oxide, as well as the more common multi-functional FR4s and phenolic resin systems. We stock a wide variety of bonding films from standard epoxy prepregs and other thermoset films to low Dk thermoplastic resins like DuPont’s FEP.

Learn more about printed circuit board mfg.Standard Printed Circuits Quality

*AS9100 D * ISO 9001:2015 * ITAR * ROHS

Standard Printed Circuits, Inc. is an independently owned manufacturer of printed circuit boards located in Sherburne, New York.

About SPC

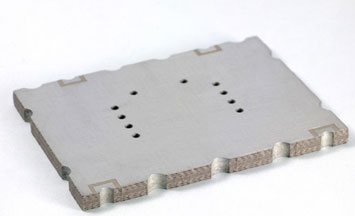

Standard Printed Circuits, Inc. has just completed a recent expansion of their facility and has begun installation of new equipment.

Read more about SPCEquipment List

Standard Printed Circuits utilizes several advanced systems to process our products.

View all of our EquipmentCapabilities

Standard Printed Circuits, Inc. circuit board manufacturing has resulted in high-quality products for an array of clients.

View our Capabilities