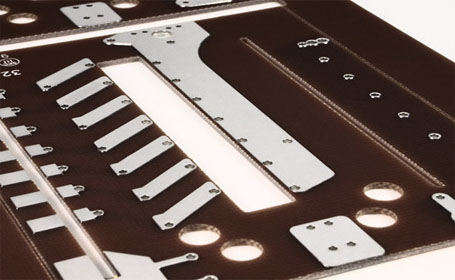

Standard Printed Circuit’s has custom manufactured over 1,000 double-sided, high-temperature printed circuit boards (PCBs) for clients from the Telecom/IT Industry. These PCBs are capable of withstanding continuous operating temperatures of 250° Celsius.

Some of the processes used to manufacture these boards included:

- Shearing all raw material to size

- Drilling all necessary holes

- Copper plating

- Chemical etching to remove excess copper material

- Primary imaging

In addition to these processes, hot air solder leveling was also performed, adding an extra layer of protective metal over the copper surface. Holding tolerances as close as ±.005″, the finished PCBs were constructed from polyimide laminate and measured 10.5″x 3″. Meeting stringent industry standards and client specifications, we delivered all finished units to our consumer’s facility in Southwestern US. The units fulfilled our customer’s high expectations for both quality and high temperature reliability.